PVC pipe seals, also commonly referred to as pipe gaskets or pipe seals, play a vital role in various plumbing, drainage, and industrial applications. These seals are essential components in joining sections of PVC (polyvinyl chloride) pipes together, ensuring a secure, watertight connection that prevents leaks and maintains structural integrity.

Here’s a detailed description of PVC pipe seals and their characteristics:

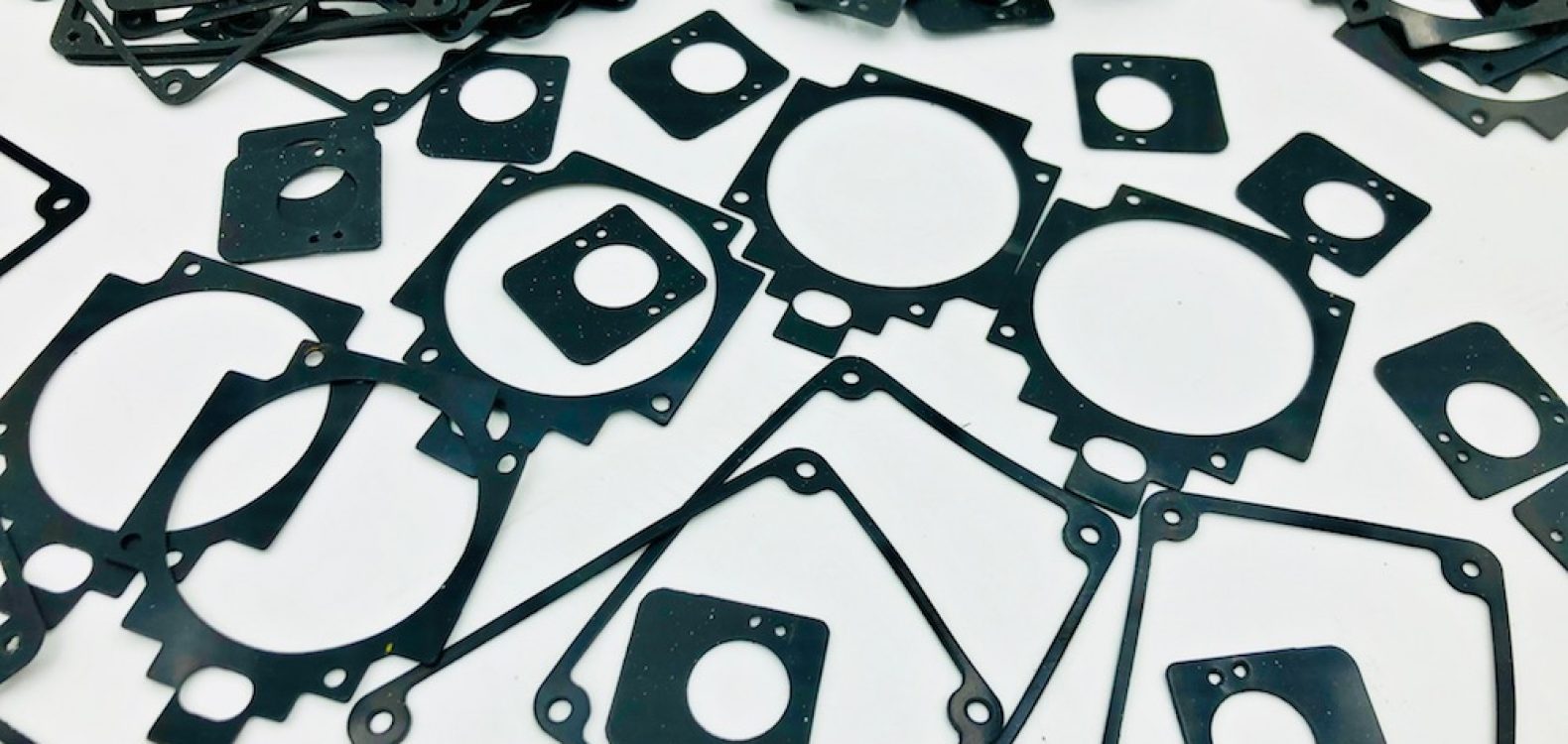

- Material Composition: PVC pipe seals are typically made from elastomeric materials such as rubber or synthetic rubber compounds. These materials offer flexibility, resilience, and resistance to deformation, allowing the seals to accommodate pipe movements and maintain a tight seal over time.

- Design and Structure: PVC pipe seals come in various designs and configurations to suit different pipe sizes, shapes, and applications. They may feature a cylindrical or conical shape with grooves, ribs, or flanges to facilitate proper alignment and sealing within pipe joints.

- Sizes and Compatibility: PVC pipe seals are available in a wide range of sizes to accommodate different pipe diameters and thicknesses. They are designed to fit seamlessly with standard PVC pipe dimensions, ensuring compatibility and ease of installation.

- Installation Method: Installing PVC pipe seals typically involves placing the seal at the joint interface between two pipes or fittings. The seal is compressed between the mating surfaces, creating a tight seal that prevents water or other fluids from escaping the system.

- Watertight Seal: One of the primary functions of PVC pipe seals is to create a watertight barrier at pipe joints, preventing leaks and seepage. The elastomeric material conforms to irregularities in the pipe surfaces, effectively sealing any gaps or imperfections that could compromise the integrity of the joint.

- Chemical Resistance: PVC pipe seals exhibit excellent resistance to a wide range of chemicals, including acids, alkalis, and solvents. This chemical resistance ensures long-term durability and reliability, even in harsh environmental conditions or corrosive applications.

- Temperature Resistance: PVC pipe seals are designed to withstand a broad temperature range, from freezing temperatures to elevated heat levels. This thermal stability ensures consistent performance and sealing effectiveness in diverse operating conditions.

- UV Resistance: Some PVC pipe seals are formulated with UV-resistant additives or coatings to protect against degradation caused by prolonged exposure to sunlight. This UV resistance helps maintain the seal’s integrity and prolong its service life, especially in outdoor or exposed installations.

- Longevity and Durability: PVC pipe seals are engineered for long-term performance and durability, offering reliable sealing capabilities for extended periods without requiring frequent maintenance or replacement.

- Cost-Effectiveness: Compared to alternative sealing methods such as solvent cement or mechanical couplings, PVC pipe seals often provide a cost-effective solution for joining pipes securely and efficiently. Their ease of installation, durability, and low maintenance requirements contribute to overall cost savings over the lifespan of the piping system.

In summary, PVC pipe gaskets are indispensable components in piping systems, providing reliable sealing solutions for various applications. With their versatile design, durability, and performance characteristics, these seals ensure leak-free connections, structural integrity, and operational efficiency in plumbing, drainage, and industrial systems.