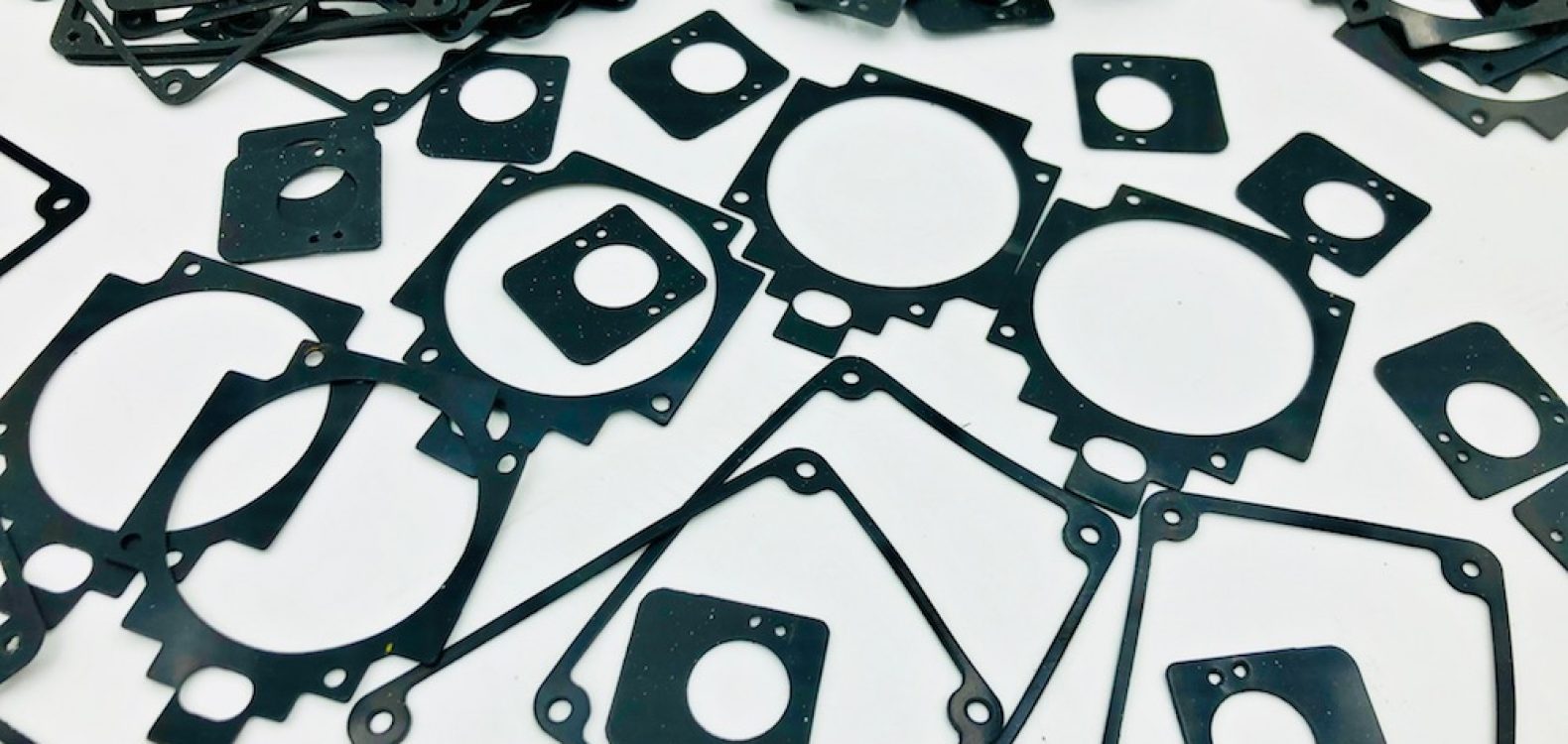

EPDM gaskets are versatile and widely used sealing components known for their exceptional durability, flexibility, and resistance to various environmental factors. These gaskets are fabricated from a synthetic rubber compound composed of ethylene, propylene, and a small amount of diene monomer. This unique formulation endows EPDM gaskets with a remarkable set of properties suitable for diverse industrial applications.

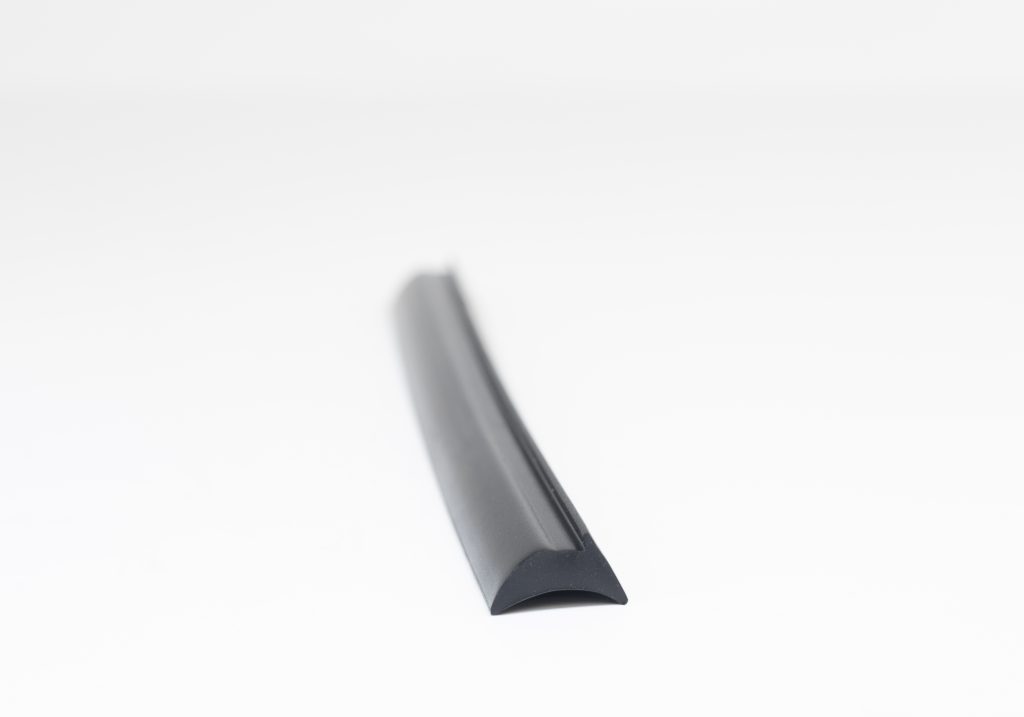

- Excellent Weather Resistance: EPDM gaskets exhibit outstanding resistance to weathering, ozone, and ultraviolet (UV) radiation, making them ideal for outdoor applications exposed to harsh environmental conditions. Whether in scorching sunlight, heavy rain, or freezing temperatures, EPDM gaskets maintain their integrity and sealing effectiveness over extended periods.

- Wide Temperature Range: EPDM gaskets can withstand a broad temperature range, from -50°C to 150°C (-58°F to 302°F), without losing their flexibility or sealing capabilities. This thermal stability makes them suitable for use in both hot and cold environments, including HVAC systems, automotive applications, and industrial machinery.

- Chemical Resistance: EPDM gaskets are inherently resistant to a wide range of chemicals, acids, alkalis, and polar solvents. This resistance ensures reliable sealing performance even in environments where exposure to corrosive substances is common, such as chemical processing plants, laboratories, and water treatment facilities.

- Excellent Elasticity and Flexibility: EPDM rubber possesses high elasticity and flexibility, allowing gaskets to conform to irregular surfaces and maintain a tight seal under varying pressure conditions. This property is particularly advantageous in applications where dynamic movement or vibration is present, such as automotive engines, piping systems, and machinery assemblies.

- Low Electrical Conductivity: EPDM gaskets exhibit low electrical conductivity, making them suitable for applications where electrical insulation is required. This property minimizes the risk of electrical leakage or interference, enhancing the safety and reliability of electrical enclosures, control panels, and electronic devices.

- Resilience to Steam and Water: EPDM gaskets demonstrate excellent resistance to steam and water, making them well-suited for sealing applications in steam piping systems, plumbing fixtures, and hydraulic equipment. They maintain their sealing integrity even when exposed to high-pressure steam or continuous water immersion, reducing the risk of leaks and water damage.