Marine and hatch cover seals play a critical role in ensuring the safety, integrity, and operational efficiency of maritime vessels. These seals serve as a barrier against water ingress, preventing leaks and maintaining the structural integrity of the vessel. Their importance cannot be overstated, particularly in harsh maritime environments where exposure to saltwater, extreme temperatures, and high pressure can pose significant challenges.

One of the primary functions of marine and hatch cover seals is to provide watertight and airtight sealing for various openings and access points on ships, including hatch covers, doors, windows, and other compartments. Hatch covers, in particular, are essential components of ships, sealing the cargo holds and protecting the cargo from water damage during transit. Properly designed and maintained seals ensure that these critical areas remain secure and protected from the elements.

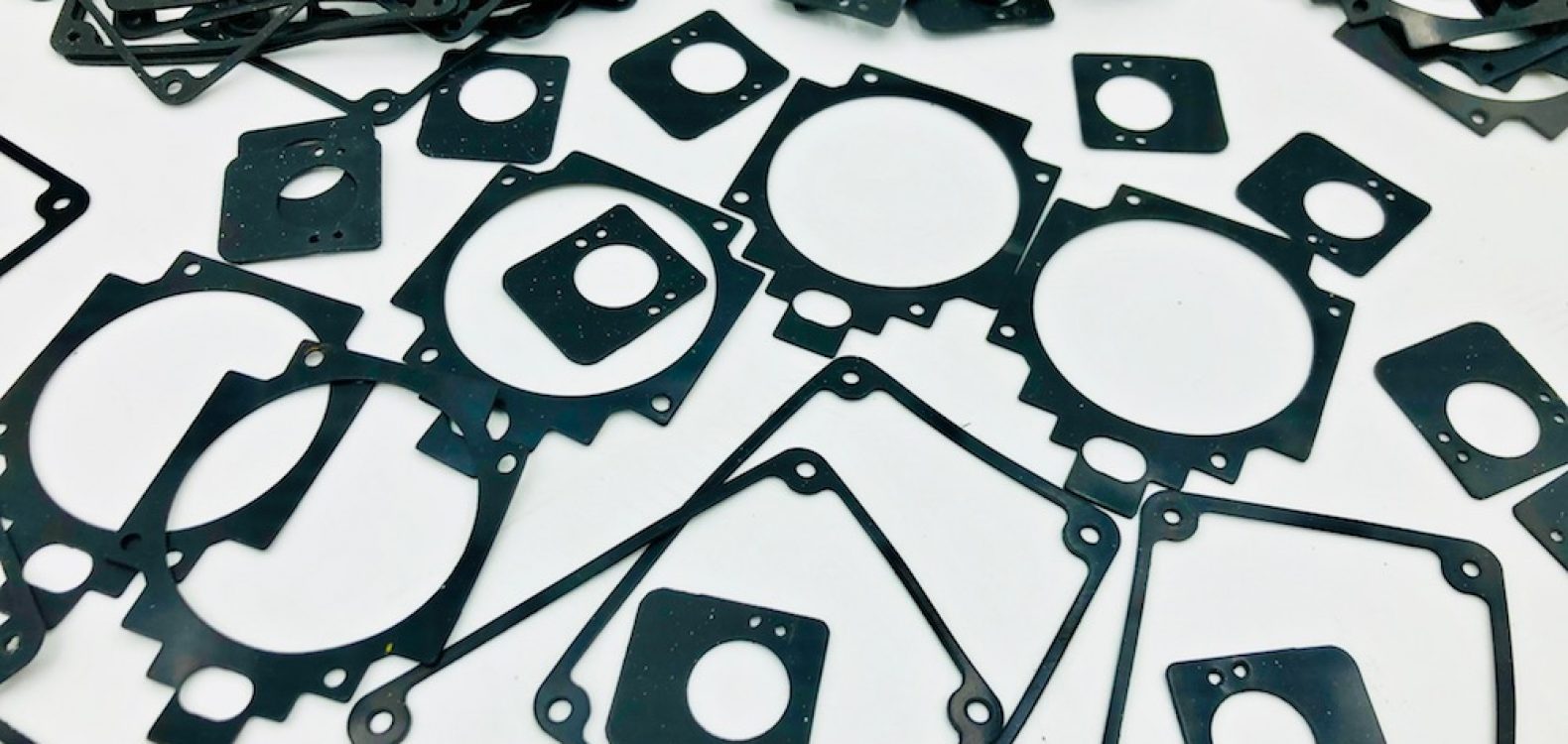

Marine seals are typically made from durable materials such as rubber, neoprene, silicone, or other synthetic compounds that exhibit excellent resilience and resistance to environmental factors. These materials are chosen for their ability to withstand prolonged exposure to seawater, UV radiation, temperature fluctuations, and mechanical stress without compromising their sealing performance.

The design and construction of marine and hatch cover seals are engineered to meet stringent industry standards and regulatory requirements. Seals must be able to accommodate the dynamic movements and deformations experienced by the ship’s structure during operation, including flexing, twisting, and compression. Additionally, they must maintain their sealing integrity over extended periods, despite constant exposure to harsh marine conditions.

Various types of seals are employed in maritime applications, including compression seals, inflatable seals, bulb seals, and lip seals, each offering unique advantages depending on the specific requirements of the application. Compression seals, for example, rely on mechanical compression to create a tight seal, while inflatable seals utilize pneumatic pressure to expand and fill gaps. Bulb seals feature a bulbous shape that provides enhanced sealing performance, especially in applications with irregular or uneven surfaces.

Proper installation, maintenance, and inspection of marine and hatch cover seals are essential to ensure their continued effectiveness and reliability. Regular inspections help identify signs of wear, damage, or deterioration, allowing for timely repairs or replacements to prevent potential leaks or failures. Additionally, proactive maintenance practices such as cleaning, lubrication, and corrosion protection can extend the service life of seals and minimize the risk of unexpected failures.

In conclusion, marine and hatch cover gaskets are indispensable components of maritime vessels, safeguarding against water ingress, maintaining structural integrity, and ensuring the safety of crew, cargo, and the environment. By selecting high-quality seals, adhering to rigorous standards, and implementing proper maintenance procedures, ship operators can mitigate risks and optimize the performance and longevity of their vessels in demanding marine environments.