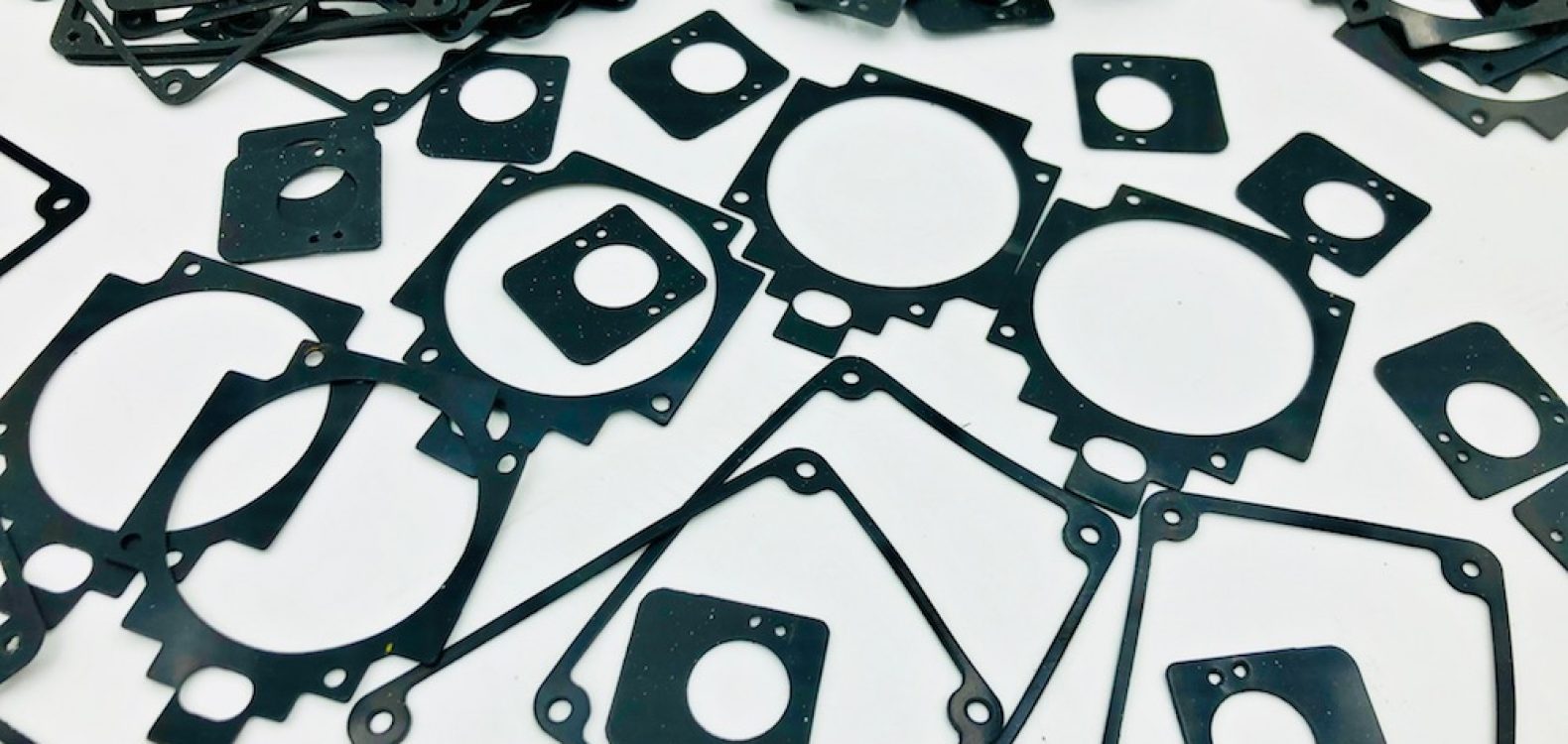

EPDM rubber seals and gaskets are widely used in various industries due to their excellent properties. Here’s a rundown:

- Weather Resistance: EPDM gaskets exhibits exceptional resistance to weathering, ozone, and UV radiation, making it suitable for outdoor applications. This makes it a popular choice for automotive weather-stripping and roofing materials.

- Temperature Resistance: EPDM can withstand a wide range of temperatures, from -50°C to +150°C (-58°F to +302°F), without significant degradation. This makes it suitable for both high and low-temperature applications.

- Chemical Resistance: It is resistant to many chemicals, acids, and alkalis, making it suitable for applications where exposure to various substances is a concern.

- Water and Steam Resistance: EPDM rubber has excellent resistance to water and steam, making it suitable for use in sealing applications where exposure to moisture is expected.

- Electrical Insulation: EPDM rubber has good electrical insulating properties, making it suitable for use in electrical insulation applications.

- Flexibility and Elasticity: EPDM rubber remains flexible even at low temperatures, allowing it to maintain its sealing properties over a wide temperature range. It also has good elasticity, which allows it to conform to irregular shapes and provide effective sealing.

- Tear and Abrasion Resistance: EPDM rubber is highly resistant to tearing and abrasion, which contributes to its durability and long service life.

- Low Permeability: EPDM rubber has low gas and vapor permeability, making it suitable for applications where sealing against gases or liquids is required.

EPDM rubber seals and gaskets find applications in various industries such as automotive, construction, aerospace, HVAC, and more. They are used for sealing purposes in doors, windows, pipes, pumps, engines, and other components where reliable sealing is essential.