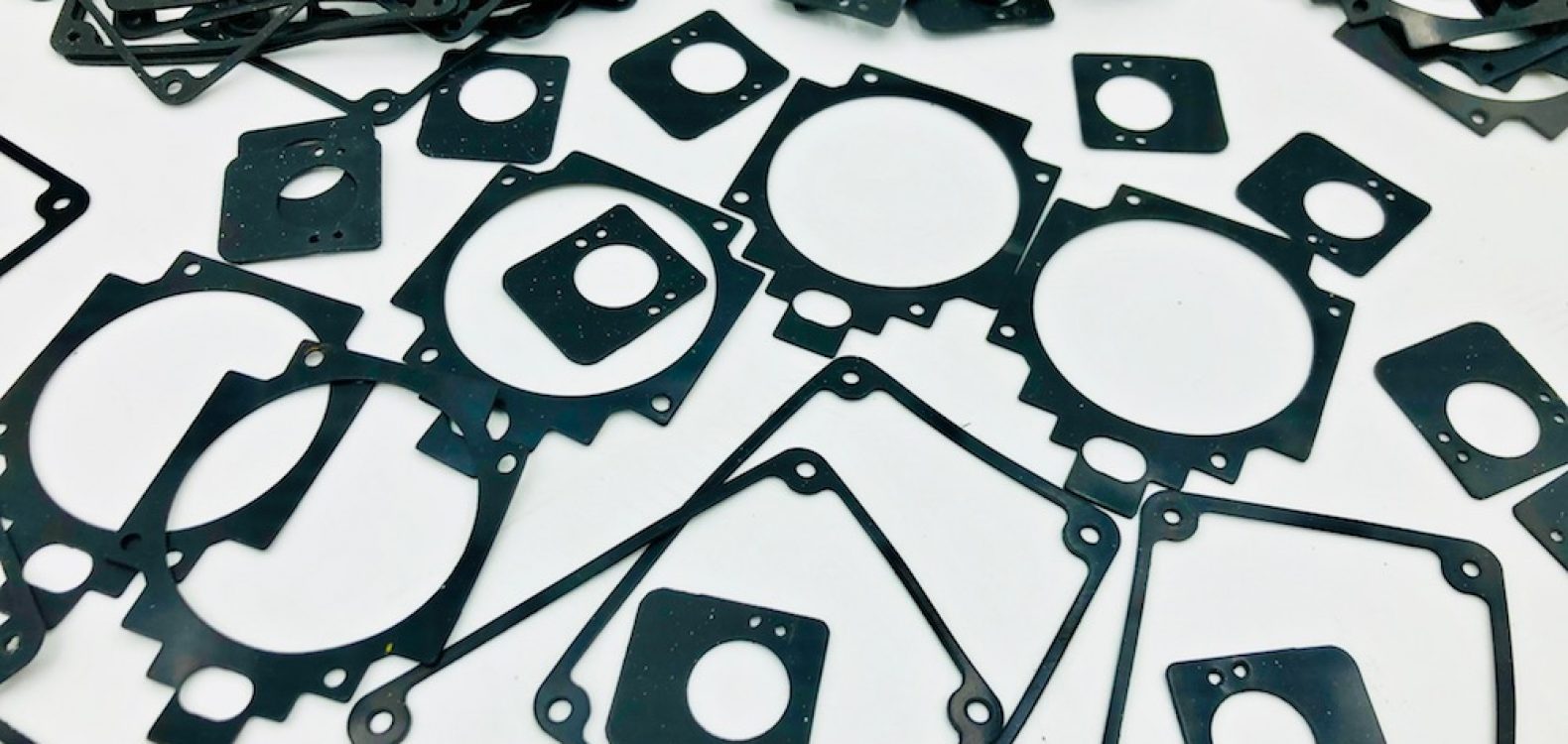

EPDM (Ethylene Propylene Diene Monomer) rubber gaskets are versatile sealing components known for their exceptional durability, flexibility, and resistance to various environmental factors. These gaskets find extensive use across diverse industries, ranging from automotive and construction to aerospace and manufacturing. Their popularity stems from a combination of advantageous properties, making them indispensable for sealing applications in demanding conditions.

- Material Composition: EPDM rubber gaskets are composed primarily of ethylene and propylene monomers, with a diene component added to impart additional cross-linking sites. This composition gives EPDM its distinctive properties, including excellent weather resistance, ozone resistance, and thermal stability.

- Weather Resistance: One of the key attributes of EPDM rubber is its exceptional resistance to weathering. Whether exposed to sunlight, moisture, or extreme temperatures, EPDM gaskets maintain their integrity over prolonged periods. This makes them ideal for outdoor applications where exposure to the elements is inevitable, such as in automotive seals and roofing systems.

- Chemical Resistance: EPDM rubber gaskets exhibit remarkable resistance to a wide range of chemicals, acids, and alkalis. This chemical inertness makes them suitable for sealing applications in industries where exposure to corrosive substances is common, such as chemical processing plants, laboratories, and pharmaceutical facilities.

- Flexibility and Elasticity: EPDM rubber possesses high elasticity and flexibility, allowing gaskets to conform to irregular surfaces and maintain a reliable seal even under dynamic conditions. This flexibility ensures a tight, leak-free seal, which is crucial in preventing fluid or gas leakage in various applications, including piping systems, HVAC units, and automotive engines.

- Temperature Resistance: EPDM rubber gaskets exhibit excellent thermal stability, retaining their mechanical properties across a wide temperature range. They can withstand both high and low temperatures without significant degradation, making them suitable for use in applications that experience extreme temperature fluctuations, such as automotive engine compartments and industrial machinery.

- UV Resistance: EPDM rubber is inherently resistant to ultraviolet (UV) radiation, making it an ideal choice for outdoor applications exposed to sunlight. Unlike some other elastomers, EPDM does not degrade or become brittle when exposed to UV rays over time, ensuring long-term performance and durability in outdoor environments.

- Electrical Insulation: EPDM rubber possesses good electrical insulation properties, making it suitable for use in electrical enclosures, cable glands, and other electrical applications. Its dielectric strength and resistance to electrical arcing make it a preferred material for sealing and insulating electrical components.

- Low Compression Set: EPDM rubber gaskets maintain their shape and sealing properties even after prolonged compression, thanks to their low compression set. This characteristic ensures that gaskets retain their resilience and sealing effectiveness over time, minimizing the risk of leaks or failures in critical sealing applications.

In conclusion, EPDM rubber gaskets offer a unique combination of properties that make them highly suitable for a wide range of sealing applications across various industries. Their resilience, durability, and versatility make them indispensable components in maintaining reliable seals in diverse environmental and operational conditions.