Infrastructure gaskets are crucial components used in various industrial and construction applications to prevent leakage, maintain structural integrity, and ensure operational efficiency. These gaskets serve as seals between two mating surfaces, effectively blocking the passage of fluids or gases under pressure or vacuum conditions. The term “infrastructure gaskets” encompasses a wide range of gasket types, materials, and designs tailored to specific requirements across diverse sectors such as oil and gas, petrochemicals, power generation, water treatment, HVAC (heating, ventilation, and air conditioning), and transportation infrastructure.

These gaskets are manufactured from various materials, including rubber (such as neoprene, EPDM, nitrile, and silicone), graphite, PTFE (polytetrafluoroethylene), metal (such as stainless steel, aluminum, and copper), and composite materials. The choice of material depends on factors such as temperature, pressure, chemical compatibility, and environmental conditions.

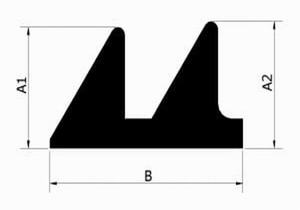

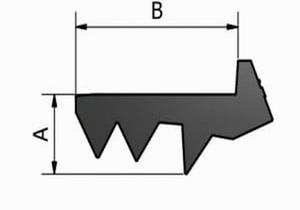

Infrastructure gaskets come in different forms to accommodate different sealing needs:

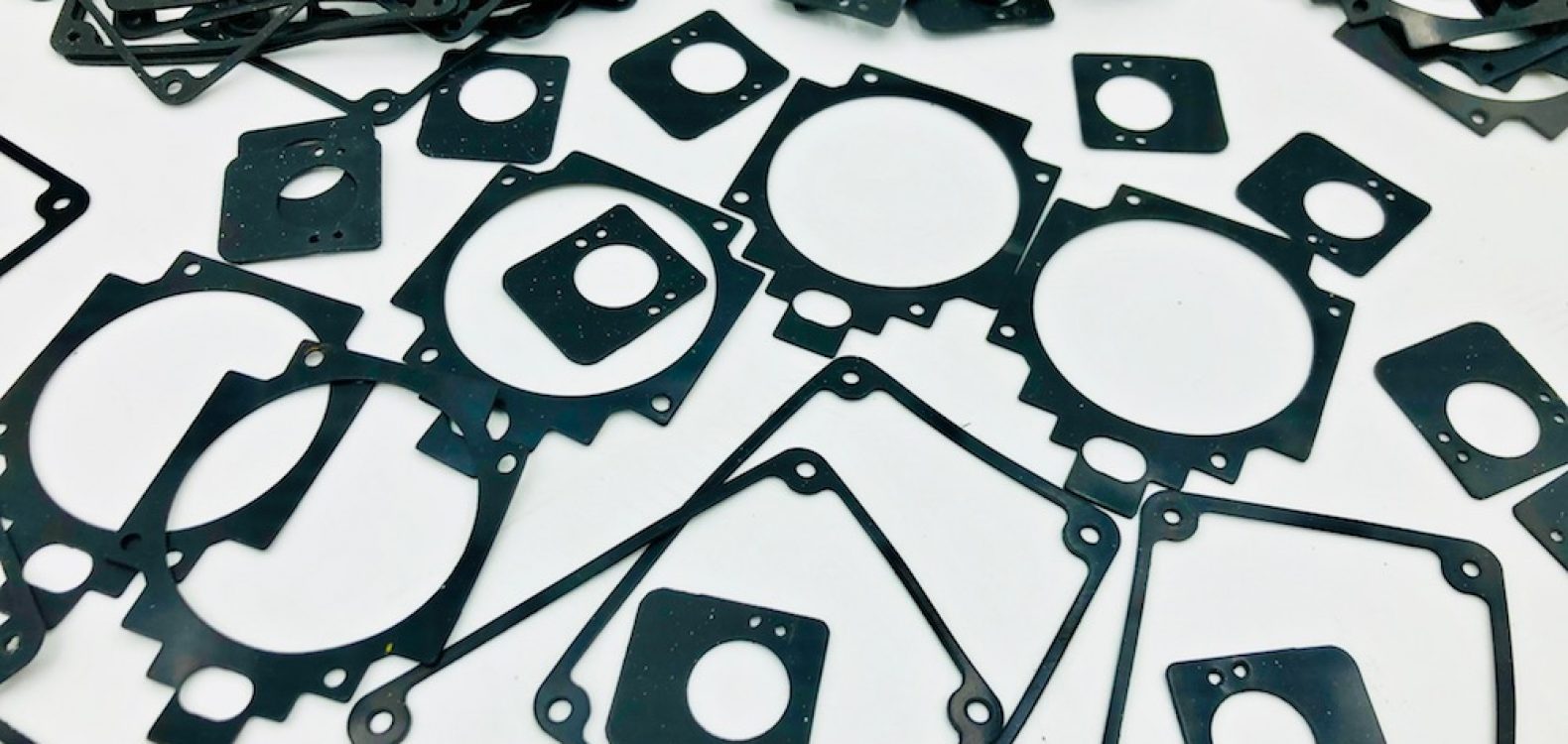

- Flat gaskets: These gaskets are typically used in applications where the mating surfaces are flat or only slightly irregular. They are cut from sheets of gasket material and can be made of rubber, cork, paper, or metal.

- Spiral wound gaskets: Constructed by winding a metal strip and a filler material (such as graphite or PTFE) into a spiral shape, these gaskets are ideal for high-pressure and high-temperature applications commonly found in the oil and gas industry.

- Ring gaskets: Also known as RTJ (Ring Type Joint) gaskets, these are metallic gaskets with an oval or octagonal cross-section. They are used in flanged connections where high pressures and temperatures are present.

- O-ring gaskets: These are round elastomeric seals with a circular cross-section, commonly used in static and dynamic sealing applications. O-rings are highly versatile and find extensive use in hydraulic systems, automotive engines, and plumbing fixtures.

- Rubber gaskets: Made from various elastomeric materials, rubber gaskets are flexible and resilient, providing excellent sealing properties. They are widely used in applications where compression and flexibility are essential, such as pipe joints and valve seals.

- Metal gaskets: Constructed from thin metal sheets, such as stainless steel or copper, metal gaskets offer superior resilience and durability, making them suitable for high-pressure and high-temperature environments.

- Composite gaskets: These gaskets combine different materials to leverage their respective strengths. For example, a composite gasket may consist of a rubber or elastomeric core sandwiched between metal or PTFE layers, offering enhanced sealing performance and chemical resistance.

The selection of the appropriate gasket type depends on factors such as operating conditions, fluid composition, temperature fluctuations, pressure ratings, and compliance with industry standards (such as ASME, ASTM, and API). Proper installation, including surface preparation and torque specifications, is crucial to ensure effective sealing and prevent leaks.

In conclusion, infrastructure seals play a critical role in maintaining the integrity and reliability of industrial and construction systems by providing robust sealing solutions tailored to specific application requirements. With a diverse range of materials and designs available, these gaskets offer versatility, durability, and performance across various sectors, contributing to the efficient and safe operation of infrastructure worldwide.