Dilatation seals also known as expansion joints or expansion seals, are crucial components used in various engineering and construction applications to accommodate movement between adjacent structural elements while maintaining their integrity. These seals are particularly essential in structures such as buildings, bridges, pipelines, and roads, where environmental factors like temperature fluctuations, seismic activity, and structural settling can cause expansion, contraction, or lateral movement.

Here’s a detailed description of dilatation seals:

- Purpose: Dilatation seals primarily serve to absorb and accommodate movement between adjacent structural elements caused by thermal expansion, seismic activity, or settlement, preventing structural damage, leaks, or failure.

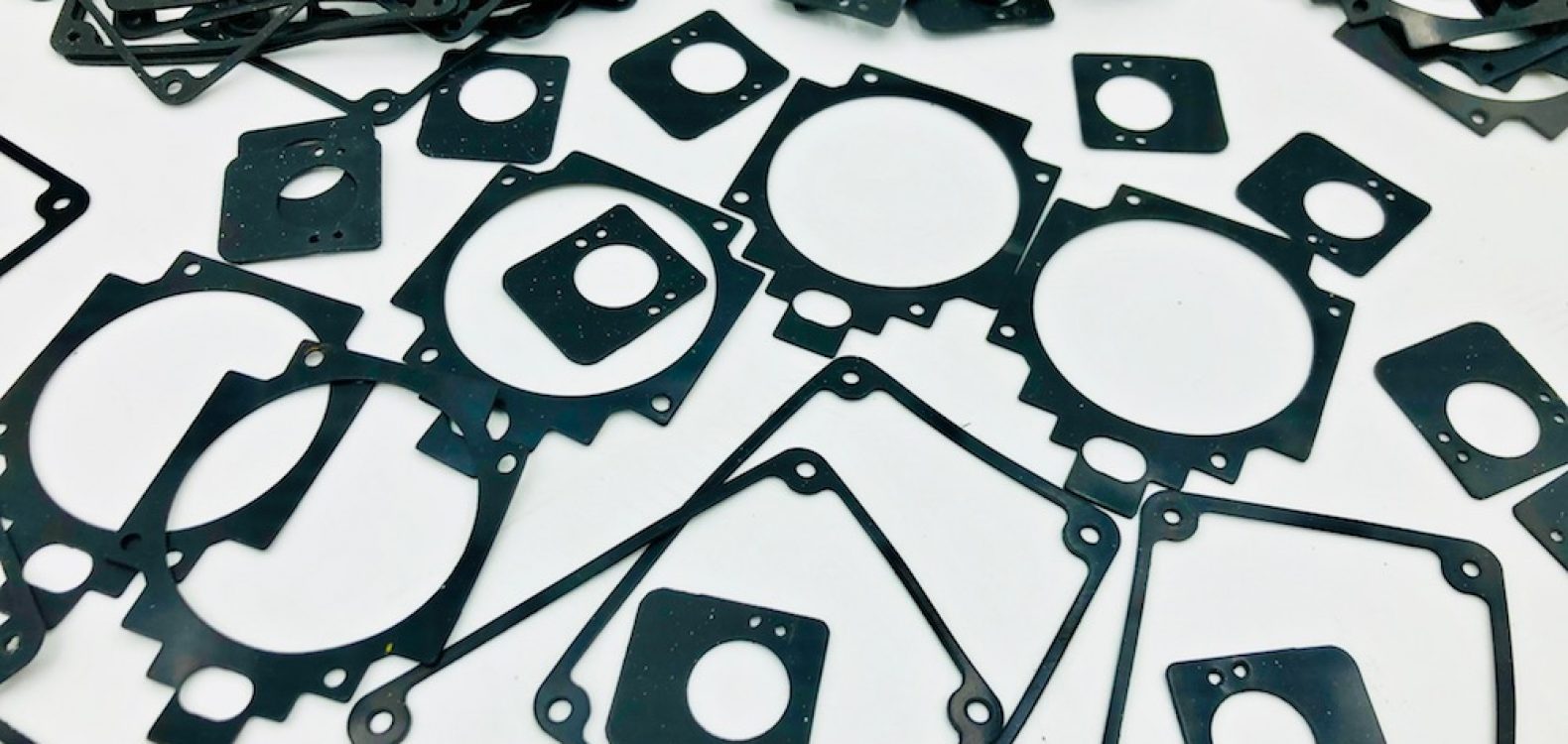

- Design and Construction: Dilatation seals are typically made from flexible materials such as rubber, neoprene, EPDM (ethylene propylene diene monomer), or silicone. These materials possess elasticity and resilience to withstand repeated movement without deterioration. The seals come in various shapes and configurations, including strip seals, finger joints, sliding plate joints, and modular joints, depending on the specific application and movement requirements.

- Installation: Dilatation seals are installed at predetermined locations where movement is anticipated, such as expansion joints in concrete slabs, gaps between building components, or connections between different segments of pipelines or bridges. Proper installation is critical to ensure the effectiveness and longevity of the seal.

- Functionality: When exposed to movement, dilatation seals flex and compress, expanding or contracting to accommodate the changes in the gap between structural elements. This flexibility prevents the transfer of stresses and loads from one element to another, reducing the risk of cracking, buckling, or deformation.

- Types of Movement: Dilatation seals can accommodate various types of movement, including axial (linear expansion or contraction along the joint), lateral (sideways movement), and angular (rotation or bending). The design and selection of the seal depend on the anticipated movement and the structural configuration.

- Environmental Resistance: Dilatation seals are designed to withstand harsh environmental conditions, including exposure to UV radiation, moisture, chemicals, and temperature extremes. High-quality materials and advanced manufacturing techniques ensure durability and long-term performance in demanding environments.

- Maintenance and Inspection: Regular inspection and maintenance are essential to ensure the proper functioning of dilatation seals. Inspections may include visual assessments for signs of damage, checking for proper alignment and movement, and cleaning debris or contaminants that could impair performance.

- Applications: Dilatation seals find widespread use in various industries and infrastructure projects, including building construction, transportation infrastructure (such as highways, bridges, and railways), water and wastewater systems, industrial facilities, and power generation plants.

In summary, dilatation gaskets play a critical role in preserving the structural integrity and functionality of infrastructure and engineered systems by accommodating movement and preventing damage or failure. Their design, installation, and maintenance are essential considerations in ensuring the long-term performance and reliability of structures and facilities.